Through the compost factory project, DN AGRAR manages efficiently the manure and increases soil fertility, actively contributing, at the same time, to the reduction of greenhouse gas emissions. This initiative demonstrates DN AGRAR’s commitment to the principles of circular agriculture, as a promoter of it.

DN AGRAR marks another step towards strengthening the circular economic model at Group level by implementing the first automated manure composting unit at Apold farm.

In parallel with the start of the operations, we have embarked on the process to obtain voluntary carbon certification for the compost produced, and by the end of 2026, we expect to receive the first carbon credits.

The integrated project built around the compost factory will generate significant economic benefits, including additional revenues for sales and from carbon credits earned through methane emission reductions.

Peter de Boer

CEO & BoD Member

DN AGRAR Group

DN AGRAR’s decision to develop compost production through a composting unit located near the Apold farm, is considered as a crucial first step. The success of this first composting factory is considered essential for expansion of such facilities to the other farms within the group.

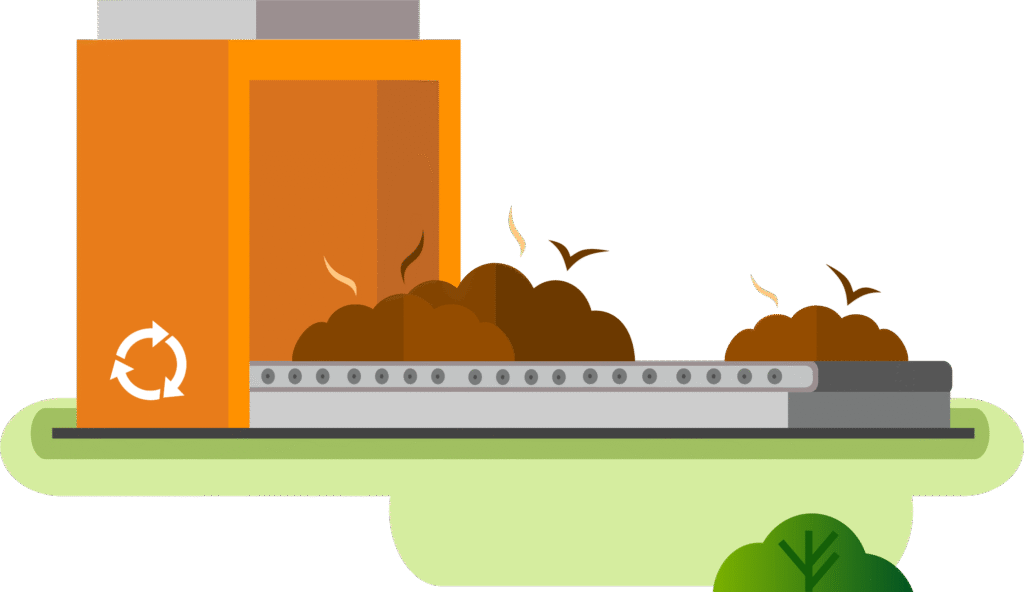

From manure to organic compost.

The composting process at DN AGRAR Apold farm.