To enhance work efficiency in our farms, we planed the installation of industrial robots in our farms: CUT, LACTO AGRAR and STRAJA.

Based on our internal analysis, using these robots in our farms, will result in a 50% reduction of manual labour, for specific operations in the milking process, after this project is implemented and finalized.

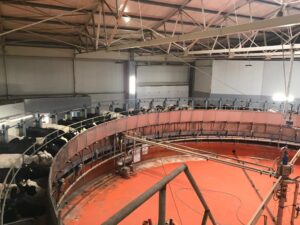

These robots are specifically designed for use in farms equipped with rotary milking parlors, which we have in Lacto Agrar and Cut farms, and in the future at the Straja farm.

Automatic dipping udder sprayer, after the milking process

This is a fully automated udder dip sprayer specifically designed for rotary parlors.

They work with most standard udder dips, automatically spraying udder after the milking clusters are removed hence the milking process ends.

The system automatically sprays udder with the post-dip solution. As a result, the udder is fully coated and protected from mastitis-causing bacteria between milkings.

- Elimination of salary and expenses for one labor position per shift

- Saving money without sacrificing udder health

- Preventing mastitis and its associated costs

- See a full return on investment after 1 year from installation

We have already started this project at two of our farms, installing this type of robot in May 2023.

With this phase finalized, the manual labor for specific operations in the milking process is reduced by 25%.

Pre-Cleaning tits and milk stimulation robot

It is well known that to minimize clinical mastitis and its associated costs, s and udders must be as clean as possible. In robot systems, cleaning udder before milking is an automatic process.

This dairy robot completely automates the whipping position by performing udder cleaning and, teat stimulation and udder wiping.

The brushes on this rotary robot remove debris from the teats and udder, reducing the possibility for infection and lowering the likelihood of both mastitis and bimodality.

As the brushes grab onto the udder, they also perform automatic pre-stimulation which can lead to faster milk let down.

Once installed, this robot requires no interaction from parlor staff.

- Eliminate salary and labor expenses for whipping and cleaning the udder

- Save money without sacrificing udder health

- Prevent mastitis and its associated costs

- See a full return on investment after 1 year from installation

This type of robot was installed in our two farm on May 2024.

With this second phase completed, we will record another reduction of manual labor with 25%, for specific operations in the milking process.

After 1 year from installation of these robots in our Lacto Agrar and Cut farms, we will record a 50% reduction in manual labor regarding specific operation in the milking process, for both farms.

After the new Straja farm is finalized and fully performing, we plan to install also these two types of robots there.